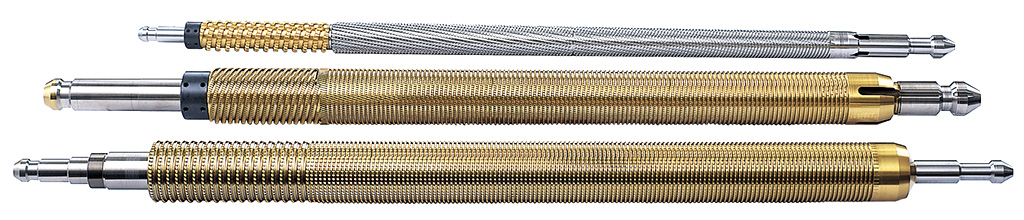

DIC Tools India is leading Broaching Tool Manufacturers, of precision machining components with high-quality. Broaching Tools is a machining process with a specially designed multi-point cutting tool called broach. This process is commonly used in the automobile industry for machining various holes, keyways, gears, etc. These Broaches Tools are a long multi-tooth cutting tool with successively deep cuts. Mostly circular shapes are obtained by broaching. This circular shape can be internal and external. We have a complete range of Broaching Tools with surface finish and better accuracy.

Advantages of Broaching Tools:

- The machining process is completed with one stroke of broach.

- Fast and easy process.

- Many shapes of profile can be easily machined.

- Doesn’t require a highly skilled operator.

- Cutting Fluids can be applied more smoothly and effectively.

- Broach can be also used for both internal and external cutting operations.

- Broaching is faster than the further machining process, resulting in a high rate of production by better the finish.

Types of Broaching Tools:

Ø Involute Spline Broaches: Involute Spline Broach is primarily used to produce internal involute profiles. These Broaches are most commonly used for high precision steering Knuckle arm, constant mesh gear, front axle, bull gear, and differential lock clutch center, and fly sprocket wheel ratchet components. The material that we used for Involute Spline Broaches is HSS M2, M35, M42, ASP2030, ASP 2052, and ASP 2062. The module range starts M1-M5 and the diameter pitch is from 8DP-40 DP. These Broaches are made using high-quality raw material acquired from leading vendors in the industry and designed by experts to offer optimum and glitch-free performance for long periods.

Ø Serration Broaches: Serration Broach that is used to make straight-sided V-Groove Profile, equally spaced in an inner circular periphery from a prebore hole of the components. These are used in arrow Space Industries, Scooter parts, etc. DIC also, Serration Broaches can be produced as per inter or external form. The Serration Broaches supplied by us are made using high-quality raw material for higher efficiency, precise design, and high strength. Push & Pull type Serration Broach offered by DIC Tools is non-corrosive that assures long-lasting life. Maximum Broach length: 2000 mm, include angle between Serration: 30°, 60°, 90°.

Ø Helical Broaches: Helical Broaches are used for the finishing process of internal helical gears of automatic transmission. Helical Broaches Ensure accuracy of internal gears. Helical Broaches are used in firearm, telecommunications, and automotive industries. DIC supports customers by providing services like Re-sharpening of Broaches, engineering, etc. The material we used is HSS M2, M35, M42, ASP2030, ASP 2052, ASP 2062. Helical Broaches are available up to 800 mm in length, and module range: 0.25 to 15.75.

Ø Square Broaches: Square Broaches are designed to generate in one-pass a standard square hole in a previously cast or drilled round hole. These Broaches are usually designed to generate, in one pass, a square hole in a previously cast or drilled round hole. Sometimes called Square Hole Broaches, they are also used to punch square holes in fixtures, jigs, and sockets. DIC is a manufacturer of Square Broaches in standard as well as non-standard material and size in all types of PVD Coatings. Moreover we provide Square Broaches in Inch and Metric sizes.

Ø Hexagon Broaches: Hexagon Broaches, also known as hex punch broaches, create a hex-shaped hole from an existing round pilot hole in a single pass. Hex Broaches are available in both Inch and Metric sizes as well as in all types of Surface Coating. Our Broaches are well suited for use in a variety of ferrous and non-ferrous materials. These tools work on almost all turning machines. The material we used for Hexagon Broaches is HSS M2, M35, M42, ASP 2030, ASP 2052, and ASP 2062. We can also supply any standard or custom Hexagon Broach in a very short time.

Ø Round Broaches: Round Broaches are capable of precision broaching on previously drilled or reamed holes, and generate a precise, clean hole that is easy to work with. The Round Broaches is a long multi-tooth cutting tool with successively deep cuts. Round Broaches length is from 149mm to 260mm or it also depends upon the need of the customers. These are internal hole broaches best suited for precise tolerances, sizing, and finish for all such applications which need precision and finish. DIC Round Broach tools are durable and non-corrosive because they are made from high-quality raw material.

Ø Round and Single KeyWay Broaches: We are Manufacturer of Keyway Broaches made using high-quality raw material for better performance and longer efficiency. These Broaches are available in Push Type and Pull Type. Keyway Broaches are also available in sets, can also supply standard as well as non-standard material and sizes. Every Broach supplied by us has a smooth finish, precise design, and high strength.